CIMT 2023 EXHIBIT WINDOW

Our company has been committed to the research of complex cutting tools and sophisticated cutting tool technology, and is constantly learning new technologies and developing new products. Naturally, turbine hob is also in our company's research and production. In recent years, through continuous efforts to explore, test and summary, we have been continuously to different needs of customers design and production of different modules, different precision levels, different tool materials, different types of turbine hob. Our company can provide customers with "private customized version" exclusive tools according to the tooth profile type and original parameters of the worm gear pair. In the process of continuous communication with customers, we actively accumulate experience, actively explore new methods and new processes, and then provide customers with stable and efficient tools, which are ultimately widely praised by customers.

The four-sided hole (six-sided hole) gear slotting cutter uses the meshing principle to process the through hole or the four-sided hole (six-sided hole) with empty slot in the gear slotting machine tool, especially the processing with symmetrical requirements on the hole edge. The tool has good shape retention, high efficiency and can be used for grinding.

Non-standard customized oblique gear cutter breaks the limitation of the original gear cutter manufacturing, and makes the angular tolerance of the same group of oblique gear cutter within 5 'according to the process requirements of the processed product. Our company adopts a new manufacturing process, which not only ensures the precision of tool manufacturing, but also improves the processing efficiency of gear shaper. Our company can undertake the design and manufacture of carbide and high-speed steel oblique gear shaper cutters, and optimize the tool parameters according to the characteristics of the processed products. According to the diagonal requirements of different types of herringbone gears, the cutting tool scheme developed by our company can provide higher processing stability, and the processing efficiency can be greatly improved by combining with the in-machine measurement system.

Exhibitor Information

Harbin Dong'an Lifeng Cutter Co.,Ltd

Address: No.8, Donghai Road, Heping Road Concentration Zone, Harbin Development Zone

Tel: 86-451-86818743

Fax: 86-451-86545528

Email: kaifabu@dalf.cn dalf@dalf.cn

Alibaba Website: www.dalf.com.cn

Company official website: www.dalf.cn

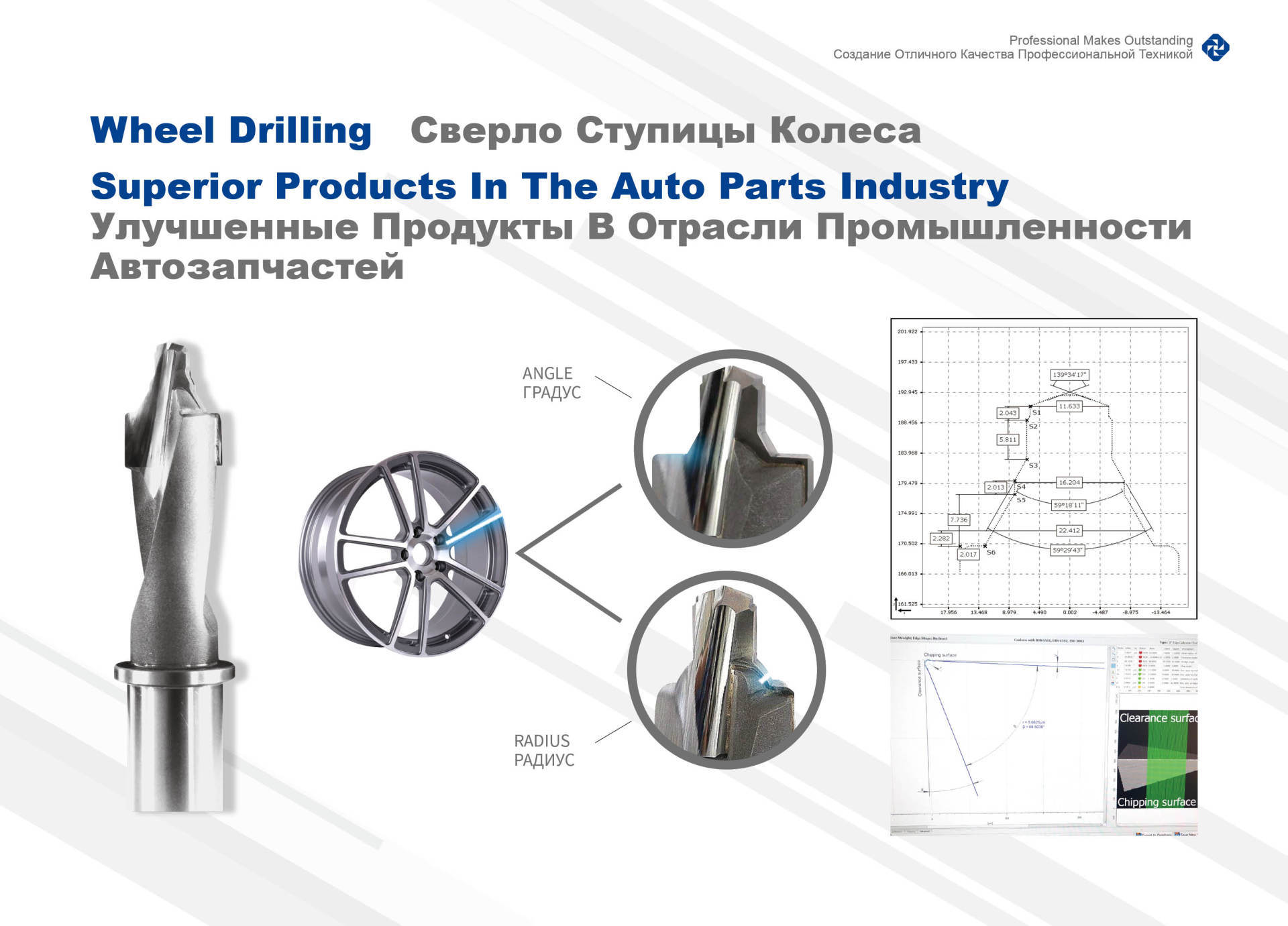

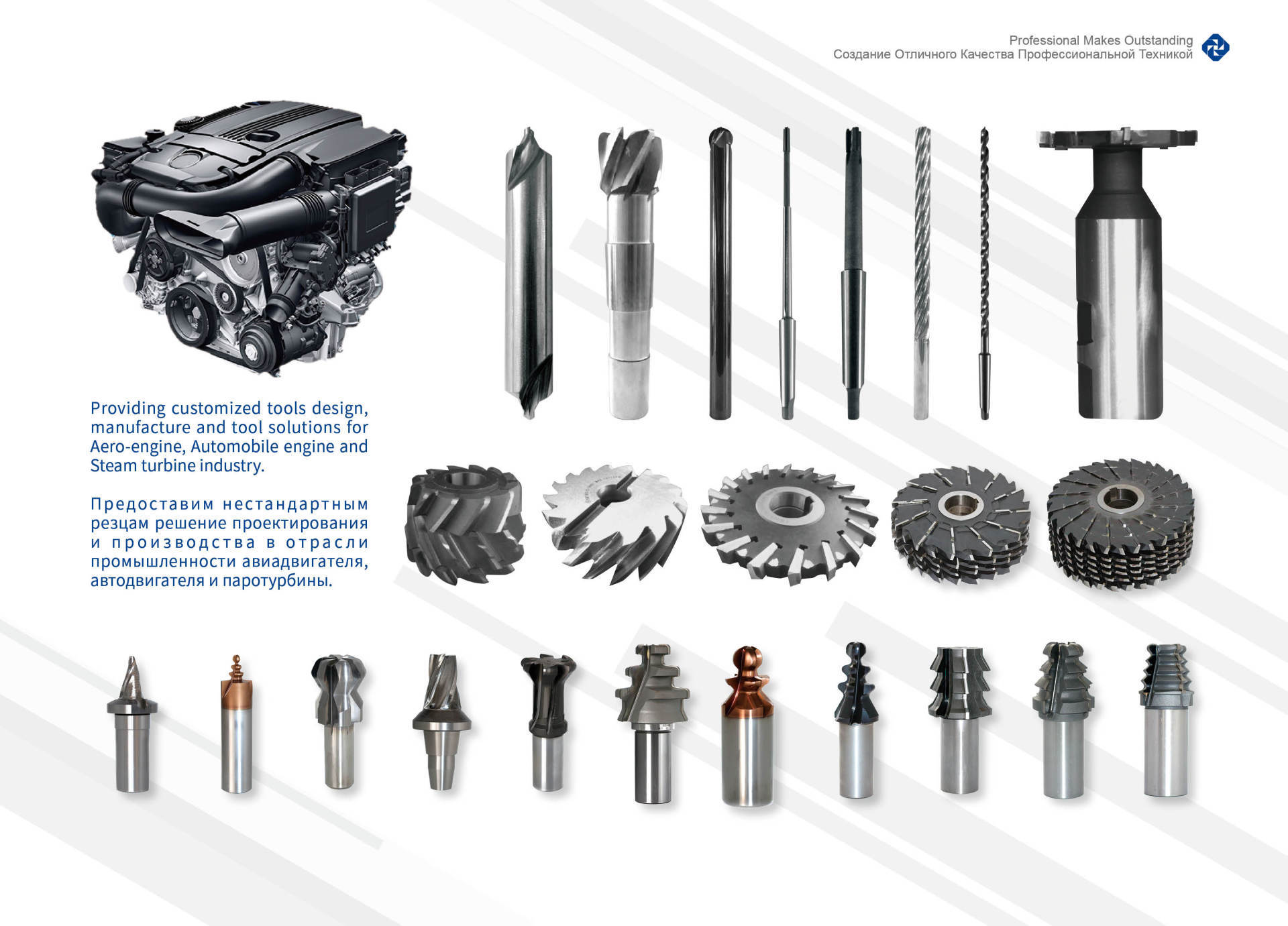

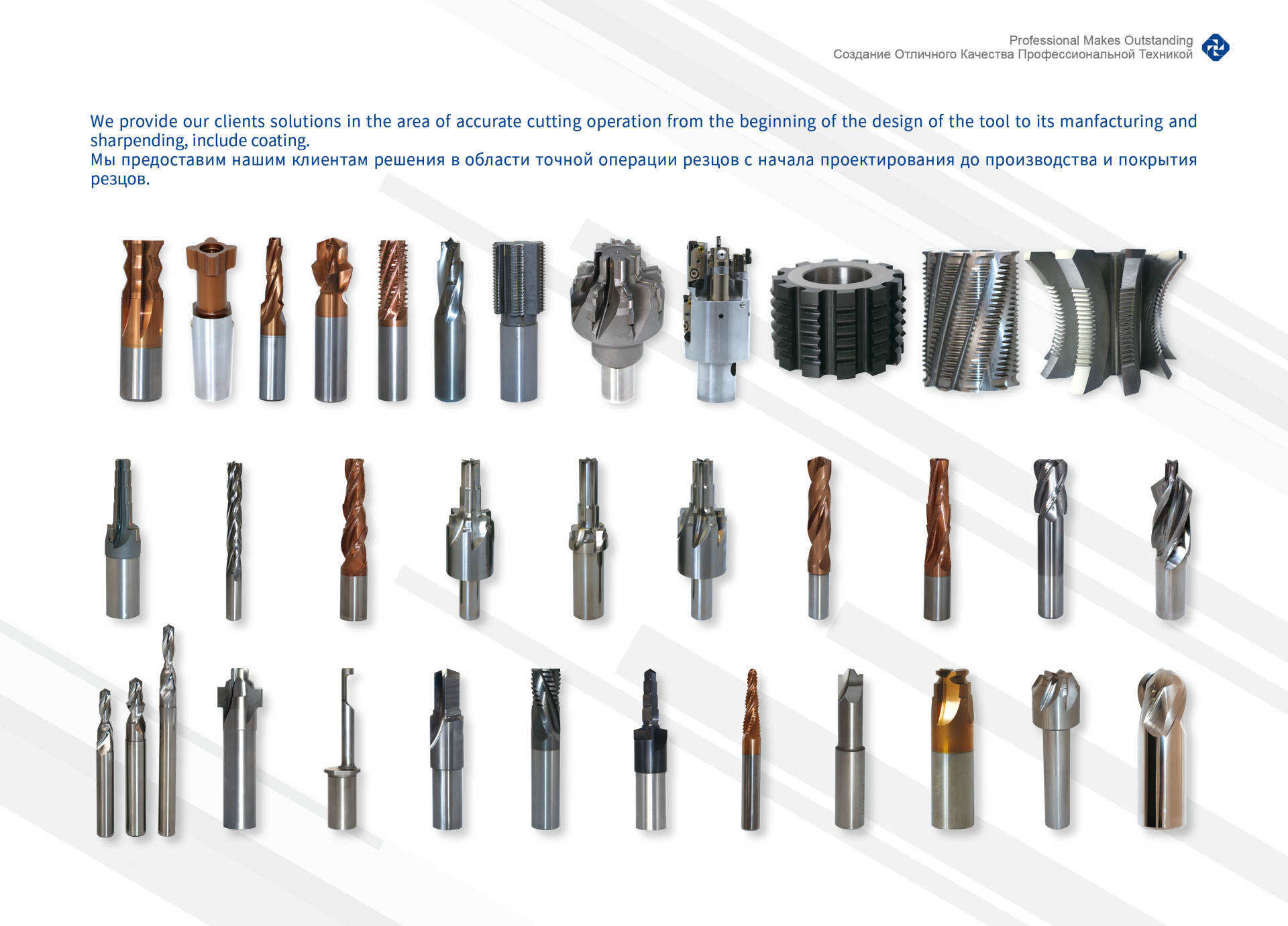

Main products and applications: The company has long provided R & D, design and manufacturing of non-standard tools for aero-engines, steam turbines and other industries, and provided overall solutions for cutting technology according to customer needs. At present, the main products are tools for difficult-to-machine materials of aero-engines, small module gear tools for helicopter reducers, combined disc milling cutters for fork blades, and line milling cutters for steam turbine rotors (blades).

Exhibition Information

CIMT2023 of the 18th China International Machine Tool Exhibition

Time: April 10-15, 2023

Venue: Beijing China International Exhibition Center (Shunyi Pavilion)

Booth: E7-A502

Harbin Dongan Lifeng Tool Co., Ltd. welcomes you to visit and guide!

Apr 03,2023